The Unsung Hero: Why the Load Cell is the Most Important Part of Your Scale

Here’s a secret most scale owners never learn until it’s too late: the digital indicator, the stainless steel platform, the rugged casing—they’re all just the supporting cast. The true star, the component that actually creates the measurement, is a small, unassuming piece of engineering called the load cell.

Think of it like a car engine. You interact with the steering wheel and pedals, but it’s the engine that makes everything go. When a load cell fails, your scale isn’t just "broken"—it’s blind. I’ve diagnosed countless "problem scales" where the issue wasn't the software or the display, but a single, fatigued load cell that was quietly skewing every measurement and costing the business money.

Let’s pull back the curtain on this vital component.

What is a Load Cell? The Scale’s Sixth Sense

A load cell is a transducer. That’s a fancy word for a device that converts one form of energy into another. In this case, it converts a mechanical force (weight) into an electrical signal.

When you place an object on your scale, the force travels through the platform and onto the load cell(s). The load cell deforms minutely—we’re talking microns, far less than the thickness of a human hair. This microscopic deformation is what gets measured and turned into the number you see on the screen.

The Workhorse: How a Strain Gauge Load Cell Works

The most common type in industrial and commercial scales is the strain gauge load cell. Here’s a simple breakdown of the magic:

- The Spring Element: This is a precisely machined block of high-strength alloy steel or aluminum. It’s designed to deform predictably under load and then spring back perfectly.

- The Strain Gauges: Bonded to this spring element are one or more strain gauges. These are incredibly fine electrical conductors arranged in a grid pattern.

- The Principle: When weight is applied, the spring element bends. This stretches the wires in the strain gauge.

- The Change: Stretching a wire increases its electrical resistance. The heavier the load, the more the strain, the higher the resistance.

- The Translation: The scale’s indicator sends a known voltage through the strain gauge. It measures the tiny change in voltage caused by the changing resistance and, using a pre-programmed formula (calibration), converts it into a weight value.

This entire process happens thousands of times per second with astonishing precision.

Common Types of Load Cells in Industrial Scales

While strain gauge is king, the design varies by application:

- Shear Beam: The most common for platform and bench scales. Rugged, cost-effective, and good for medium to high capacities.

- Single Point (Platform): Used in small bench and retail scales. One cell handles off-center loads, making it ideal for dynamic weighing.

- Compression: Used in high-capacity applications like tank, silo, and floor scales. They are built to handle massive vertical forces.

- S-Type (Tension/Compression): Often used in crane scales, hoppers, and applications where the load can be suspended (tension) or seated (compression).

The 5 Warning Signs of a Failing Load Cell

Load cells are tough, but they’re not invincible. Watch for these symptoms:

- Inconsistent Readings: Weigh the same item multiple times and get different results. This is the most common early sign.

- Drift: The display number won’t settle. It creeps up or down even when nothing is being added or removed.

- Tare/Zero Issues: The scale won’t zero out properly, or the zero point drifts on its own.

- Non-Linearity: The scale is accurate at low weights but becomes increasingly inaccurate as the weight increases (or vice versa).

- Physical Damage: Visible dents, cracks, or corrosion on the load cell body. Severe overload can cause permanent deformation.

The #1 Enemy of Load Cells: Overload

This cannot be overstated. Exceeding the rated capacity of your scale is the fastest way to kill a load cell. The damage is often not immediate but cumulative. Dropping a heavy item onto the platform creates a shock load that can be 2-3 times the static weight, delivering a hammer blow to the sensitive internal components.

Can You Replace a Load Cell Yourself?

Technically, yes. Practically, it’s not recommended for most owners.

- It’s a Precision Task: Load cells must be installed perfectly level and with the correct mounting hardware and torque. Improper installation creates binding or side-load, which destroys accuracy.

- Re-Calibration is Mandatory: A new load cell will change the scale’s performance. It must be professionally calibrated with certified weights to be accurate and, if applicable, legal-for-trade.

- Diagnosis is Key: The problem might not be the load cell. It could be the junction box, cabling, or indicator. A professional technician can accurately diagnose the issue.

How to Protect Your Load Cells and Extend Scale Life

- Respect the Capacity: Always stay well within the scale’s maximum limit. Use a scale with a higher capacity if needed.

- Avoid Shock Loading: Never drop items onto the scale. Place them gently.

- Ensure a Stable Foundation: Mount the scale on a solid, level surface to prevent twisting forces.

- Protect the Environment: Use scales with appropriate IP ratings to keep moisture and corrosive agents from reaching the load cells.

- Schedule Regular Maintenance: Include a load cell check in your regular calibration and service schedule.

The Bottom Line: Guard the Core

The load cell is where the physical world meets your digital data. Its health is synonymous with your scale’s accuracy. By understanding how it works and treating it with care, you protect the integrity of every single measurement your business depends on.

Is your scale showing signs of load cell distress? Don't guess. Schedule a professional diagnostic service with our technicians to accurately diagnose the issue and restore your scale to peak performance.

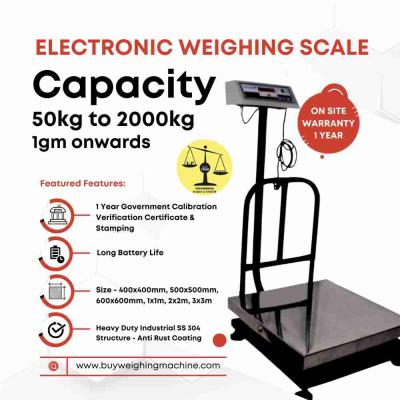

Weighing Scale

Weighing Scale