Stop Counting, Start Knowing: How a Parts Counting Scale Can Slash Your Inventory Costs

Let's be real. Manual inventory counting is a necessary evil. It's tedious, prone to human error, and eats up valuable hours your team could spend on more productive tasks. I've walked into warehouses where a quarterly inventory count meant a weekend of overtime and still resulted in frustrating discrepancies that hurt the bottom line.

But what if you could count 10,000 tiny screws in seconds, with perfect accuracy?

That's the power of a parts counting scale. It doesn't just weigh; it does the math for you. This isn't a niche tool—it's a fundamental piece of technology for any business that handles large quantities of small items. The return on investment can be staggering.

So, How Does a Counting Scale Actually Work? It's Brilliantly Simple.

The principle is elegant. The scale uses weight to calculate quantity. Here's the step-by-step:

- Know the Weight: First, you give the scale a reference. You place a sample of your parts—say, 10 bolts—on the scale.

- Set the Sample: You tell the scale that this is a sample of "10 pieces."

- The Magic Calculation: The scale's internal computer now knows the average weight of a single part. It divides the total weight of your sample by the number of pieces to find this critical value.

- Count Anything: Now, when you dump a large quantity of those same bolts onto the scale, it takes the total weight and divides it by the average unit weight. In a flash, it displays the total piece count.

The larger and more accurate your sample size, the more precise your final count will be. This is why high resolution and accuracy are so crucial in a counting scale.

The Staggering ROI: More Than Just a Time-Saver

The benefits go far beyond speed. A parts counting scale directly impacts your profitability:

- Eliminate Shrinkage: Pinpoint exactly what comes in and what goes out, reducing loss from error or theft.

- Speed Up Operations: Count parts for production kits or customer orders in seconds, not minutes.

- Improve Inventory Accuracy: Achieve near-perfect inventory records, leading to better purchasing decisions and fewer stock-outs.

- Reduce Labor Costs: Free your staff from mind-numbing counting tasks and redeploy them to value-added work.

Choosing the Right Parts Counting Scale: A 3-Step Guide

Not all counting scales are the same. Picking the wrong one can lead to inaccurate counts. Follow this logic:

Step 1: Determine Your Smallest Part Weight.

This is the most important step. What is the absolute lightest item you need to count? A tiny microchip? A specific washer? Find out its weight in grams. This determines the resolution you need.

Step 2: Understand Resolution and Capacity.

This is the classic trade-off.

- Capacity: The maximum weight the scale can handle.

- Resolution: The smallest weight change the scale can detect.

You need a scale that can sense the weight of your smallest part (high resolution) while still being able to handle the total weight of your largest count (high capacity). For counting very small items, you'll need a high-precision balance.

Step 3: Match the Scale to Your Workflow.

- Bench Scale with Counting: Perfect for general warehouse use, counting parts for orders. Good capacity and decent resolution.

- High-Precision Balance: Essential for electronics, jewelry, or pharmaceutical components where the unit weight is minuscule.

- Portable Counting Scale: Ideal for doing inventory checks right on the shelf.

Pro Tips for Flawless Counting Accuracy

Even the best scale needs to be used correctly.

- The Sample Size Matters: The more pieces in your sample, the more accurate the average unit weight. For bulk items, use a sample of 50, 100, or even 500 for the best accuracy.

- Beware of "Count by Weight" Pitfalls: This method only works if all the parts are identical. If your "bolts" are from different batches with slightly different weights, your count will be off. Consistency is key.

- Use the "Auto-Sample" Feature: Many modern scales have an "Auto-Sample" function. You add parts one by one, and the scale automatically calculates the average weight as you go, making the process incredibly accurate and easy.

- Keep it Clean and Calibrated: Dust on the pan can affect the weight of very small samples. Regular cleaning and calibration are essential.

The Bottom Line: It's an Intelligence Tool

A parts counting scale transforms your inventory from a best guess into a precise science. It provides the data you need to control costs, satisfy customers, and run a tighter, more efficient operation. In today's competitive landscape, that kind of intelligence isn't just convenient—it's critical.

Ready to bring precision to your inventory? Browse our range of High-Resolution Counting Scales and find the perfect model for your business needs.

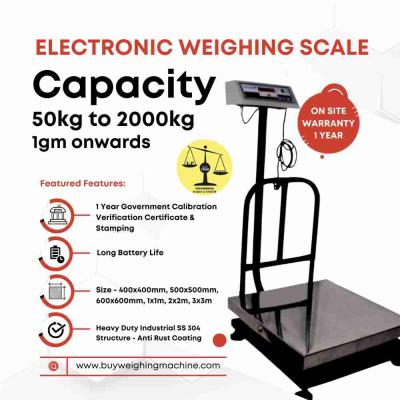

Weighing Scale

Weighing Scale