Industrial Scale Maintenance: Your Simple Checklist for Peak Performance & Longevity

Let me ask you a question. When your delivery truck needs an oil change, you schedule it. When your HVAC filter gets dirty, you replace it. But when was the last time you gave your industrial scale a bit of preventative care?

For many businesses, the answer is "when it breaks." And that's an expensive way to operate. A 200/-Rs service call for a cleaning and check-up can prevent a 2,000/-Rs repair from a corroded load cell or a shattered platform due to unseen damage.

Good industrial scale maintenance isn't about complex engineering; it's about consistent, simple habits. Here is your no-nonsense, practical checklist to keep your scales accurate, reliable, and out of the repair shop.

The Philosophy: An Ounce of Prevention

Think of maintenance in two layers:

- Hygiene & Housekeeping: Removing contaminants that cause damage.

- Operational Integrity: Checking for issues before they cause failure or inaccuracy.

Your Daily Maintenance Routine (5 Minutes)

These are quick visual and cleaning tasks to do at the start or end of a shift.

- Wipe Down the Platform: Use a clean, soft cloth. For general dust/dirt, a damp cloth is fine. For sticky residues, use a mild, non-abrasive cleaner. Avoid harsh chemicals, solvents, or abrasive pads that can damage the surface and load cells.

- Check for Debris: Look under the platform and around the scale base. Remove any packing material, wrappers, or product debris that could interfere with the scale’s movement or create a dirt trap.

- Visual Inspection: Give the scale a quick once-over. Look for new dents, cracks, or signs of corrosion, especially on weld points and load cell areas.

- Power Check (if battery-operated): Ensure the battery indicator shows sufficient charge for the shift.

Your Weekly Maintenance Routine (10 Minutes)

Set aside a bit more time once a week for a more thorough check.

- Zero & Span Check:

- Ensure the scale is on a level surface.

- Press tare/zero. The display should read "0" cleanly.

- Place a known test weight (even a sealed, unopened bag of known weight works) on the center of the scale. Does it display the correct weight? Note any discrepancy.

- Inspect the Cables: Check the cable running from the indicator to the scale platform for any cuts, pinches, or damage. Ensure connectors are secure.

- Clean Thoroughly: If in a washdown environment (food, chemical), perform your full sanitation routine. Ensure the scale is powered off and disconnected if permissible, and that it has the proper IP rating for the cleaning method.

- Check for Level: Place a small spirit level on the platform. A scale that is not level cannot be accurate.

Your Monthly / Quarterly Maintenance Routine

This is where you partner with your equipment.

- Corner Load Test: Place your test weight in the center of the platform and note the weight. Move the same weight to each of the four corners. The readings should be very close to the center reading. Significant variation indicates a potential load cell or mounting issue.

- Examine Critical Components: Look closely at load cell areas, pivot points, and check for any loose hardware or fasteners. (Do not attempt to disassemble sealed components).

- Review Performance Logs: If you record checkweigh data, look for trends of drift or inconsistency.

- Schedule Professional Service: This is the most important step. Based on your usage, schedule your professional calibration and inspection. A certified technician will perform diagnostics you can't do, like checking internal components and calibrating with certified weights.

Maintenance by Scale Type: Special Considerations

- Floor & Platform Scales: Focus on the underside. Moisture, dust, and pests can accumulate here, causing corrosion. Keep the area clear and dry.

- Bench Scales: The enemy is overload. Enforce rules against placing excessively heavy items on them. Check the bench surface for stability.

- Crane Scales: Inspect the hook, shackle, and swivel for wear and deformation monthly. Check the battery and charging contacts for corrosion.

- Washdown Scales (Stainless Steel): After cleaning, always dry the scale thoroughly with a clean cloth, especially around seams and display covers, to prevent water ingress and mineral spotting.

The 3 "Never-Ever" Rules of Scale Maintenance

- Never Use a Pressure Washer on a scale not explicitly rated for it (IP66 or higher). The force can destroy seals, damage load cells, and force water into electronics.

- Never Ignore an Error Code. Modern scales display error codes (like "Err" or specific numbers). Consult the manual. An error code is your scale crying for help—address it immediately.

- Never Perform Internal Repairs or Adjustments on legal-for-trade or sealed scales. You will void the approval and likely make the problem worse.

The Bottom Line: Maintenance is a Dialogue

Your scale is a partner in your operation. These simple maintenance routines are how you listen to it. A strange sound, a drifting zero, a small crack—these are its way of telling you something is wrong before it becomes a catastrophic failure.

Investing ten minutes a week in care is the cheapest insurance policy you can buy for a critical piece of your business infrastructure.

Don't have a reliable test weight or maintenance kit? Explore our selection of Scale Maintenance Kits and Certified Test Weights to properly equip your team.

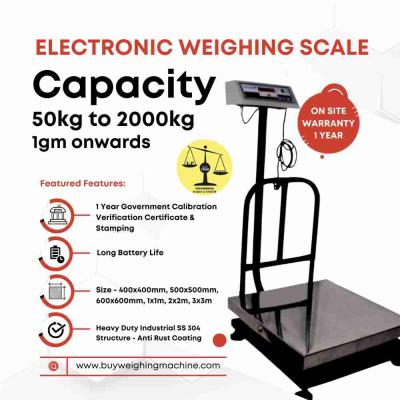

Weighing Scale

Weighing Scale