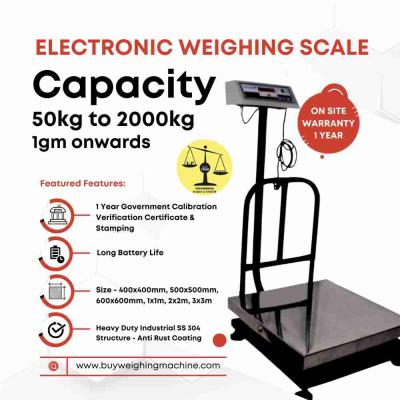

Beyond the Numbers: The Surprising Science Inside Your Electronic Weighing Machine

You see it every day. You place an item on the platform, a number flashes on the digital display, and you go about your business. It seems simple, almost magical. But inside that rugged casing of your electronic weighing machine is a world of precise engineering and fascinating physics.

I remember a client who was convinced his new scale was "broken" because the weight would waver by a few grams. After a quick visit, we found it was placed directly under an HVAC vent. The constant breeze and temperature shifts were the real culprits, not the scale. It was a perfect example of how understanding the "how" makes all the difference.

So, let's pull back the curtain. How does this piece of technology turn a physical force into a reliable digital number?

The Beating Heart: It's All About the Load Cell

If an electronic weighing scale had a heart, it would be the load cell. This is the component that does the actual "sensing." While there are different types (like hydraulic and pneumatic), the vast majority of modern industrial and commercial scales use a strain gauge load cell.

Here’s a simple analogy: think of a metal spring. When you push down on it, it compresses slightly. The heavier you push, the more it compresses. A load cell works on a similar principle, but the "compression" is microscopic and measured with incredible precision.

The "Aha!" Moment: How Strain Gauges Work

Bonded to the load cell is a tiny, intricate component called a strain gauge. It looks like a little foil spiderweb. This is where the real magic happens.

- Apply Weight: When you place an object on the scale, the force causes the load cell to deform (or "strain") ever so slightly.

- Resistance Change: This tiny deformation stretches the fine wires in the strain gauge. When wires are stretched, their electrical resistance increases.

- Measuring the Change: The scale's indicator sends a constant electrical signal through the strain gauge. As the resistance changes, the properties of this electrical signal change proportionally.

- Conversion to Weight: The indicator reads this change in signal, translates it via a pre-calibrated formula, and voilà—you get a clean, digital weight reading on the display.

This entire process happens millions of times a second, which is why the display updates in real-time. It's a continuous conversation between the load cell and the indicator.

Busting 3 Common Myths About Electronic Weighing Machines

Let's clear up some widespread misconceptions I hear all the time.

Myth 1: "The higher the capacity, the better the scale."

Truth: This is a classic mistake. Using a 1000 kg scale to weigh 5 kg packages is like using a sledgehammer to crack a nut. The scale's readability (the smallest division it can display) is what matters for light items. For accuracy, you should ideally be weighing within the 10% to 90% range of the scale's capacity.

Myth 2: "Once I calibrate it, it's accurate forever."

Truth: I wish this were true! Load cells can drift over time due to fatigue, mechanical shock (like dropping heavy items), and temperature changes. Regular calibration against certified weights is not just a good practice—it's essential for maintaining accuracy and ensuring your measurements are legally valid for trade.

Myth 3: “Digital scales are too delicate for my tough environment.”

Truth: Modern industrial scales are built like tanks. The key is choosing the right one. A scale with a high IP (Ingress Protection) Rating (like IP66 or IP67) is sealed against dust and powerful water jets, making it perfect for food processing or washdown areas. There are even intrinsically safe scales for hazardous environments where sparks could be catastrophic.

4 Pro Tips to Keep Your Electronic Scale Accurate for Years

Your scale is a precision instrument. Treat it right, and it will be a loyal workhorse.

- Find a Stable Home: Place your scale on a solid, level, and vibration-free surface. That wobbly wooden floor in the corner is your accuracy's worst enemy.

- Avoid the "Shock" Factor: Never drop items onto the platform. This can permanently damage the load cells, leading to costly repairs or replacement. This is the most common cause of premature scale failure I see.

- Perform Regular Calibration: Don't wait for a problem. Schedule regular calibrations based on your usage intensity and the critical nature of your measurements. When in doubt, consult the manufacturer's guidelines.

- Keep it Clean: Dust, debris, and especially spilled liquids can interfere with the scale's mechanics and electronics. A simple, regular cleaning routine goes a long way.

The Bottom Line: It's a Tool, Not a Toy

An electronic weighing machine is a marvel of engineering that translates real-world force into actionable data. Understanding how it works isn't just academic—it empowers you to choose the right tool, use it correctly, and maintain its accuracy, which directly protects your profits.

Is your scale living in a tough environment? Learn how to protect your investment with our guide to: Understanding IP Ratings for Industrial Scales.

Weighing Scale

Weighing Scale