Beyond "Rugged": The Simple Guide to IP Ratings That Will Save Your Scale

I’ll never forget the call from the owner of a seafood processing plant. "My new scale is dead," he said, frustrated. "It's supposed to be industrial!" When we got there, we found the scale—sold as "heavy-duty"—was completely corroded inside after just a few weeks of being hosed down. The problem? It had no meaningful IP rating.

The term "industrial" is not enough. In the real world, industrial means flour dust in a bakery, chemical spills in a lab, and high-pressure steam cleaning in a meat-packing plant. Your scale needs specific protection against these enemies.

This is where the IP rating comes in. It's not marketing fluff; it's an international standard (IEC 60529) that gives you a clear, unbiased way to know exactly what your scale can handle.

IP Rating Meaning: Breaking Down the Code

"IP" stands for Ingress Protection (or sometimes, International Protection). It's always followed by two digits (e.g., IP67). Each digit has a specific meaning.

The First Digit: Solid Particle Protection (Dust)

This number, from 0 to 6, tells you how well the scale is sealed against dirt, dust, and other solid objects.

- 5 (Dust Protected): Some dust may enter, but not enough to interfere with the operation of the equipment. This is good for most warehouse and factory environments.

- 6 (Dust Tight): A complete seal against dust. No dust can enter. This is critical for fine particles like flour, cement dust, or powdered chemicals.

The Second Digit: Liquid Ingress Protection (Water/Moisture)

This number, from 0 to 9, is often the most critical. It defines protection against water.

- 5 (Water Jets): Protection against water projected from a nozzle (6.3mm) from any direction. It can handle washdowns, but not sustained or high-pressure immersion.

- 6 (Powerful Water Jets): Protection against powerful water jets (12.5mm nozzle). This is the standard for most industrial washdown environments.

- 7 (Immersion up to 1m): Protected against the effects of temporary immersion in water (up to 1 meter for 30 minutes). This does NOT mean it's safe for continuous submersion or high-pressure cleaning while submerged.

- 8 (Continuous Immersion): Protected against continuous immersion under conditions specified by the manufacturer. This is for scales that are permanently submerged or used in very wet conditions.

The Ratings You Need to Know: A Real-World Guide

Let's translate these codes into practical advice.

- IP65: The All-Rounder. Sealed against dust and low-pressure water jets. Perfect for indoor environments where occasional spills or cleaning might occur. Think warehouse floors or workshops.

- IP66: The Washdown Workhorse. Dust-tight and protected against powerful water jets. This is the gold standard for food processing, beverage, and pharmaceutical plants where equipment is regularly hosed down with chemicals and hot water.

- IP67: The Spill & Splash Specialist. Dust-tight and can survive accidental immersion. Imagine a scale in a meat processing plant that might get fully submerged during a deep clean, or one on a dock that could be splashed by waves. It can handle a quick dunk.

- IP68: The Submersion Expert. Built for continuous immersion. This is for highly specialized applications, like scales used in water treatment plants or permanently installed in tanks.

The Cost of Getting It Wrong

Choosing a scale with an insufficient IP rating is a recipe for failure:

- Premature Failure: Water and dust ingress will destroy sensitive electronics and corrode load cells, leading to erratic readings and total breakdown.

- Costly Downtime: A failed scale on a production line can halt the entire operation, costing thousands per hour in lost productivity.

- Food Safety Risks: In food environments, a scale that can't be properly sanitized can harbor bacteria, leading to contamination and regulatory nightmares.

Your 3-Step Checklist for Choosing the Right IP Rating

- Analyze Your Cleaning Routine: Do you wipe it down, spray it with a hose, or send it through a full industrial washer? IP66 is typically the minimum for any hose-down area.

- Consider Your Contaminants: Is it just dust, or is it conductive metal dust? Is it sugary syrup, corrosive chemicals, or salty air? For corrosive materials, you need a scale with both a high IP rating and a stainless-steel construction.

- Don't Over-Specify: An IP68 scale is overkill and more expensive for a dry, dusty warehouse. Match the rating to your actual environment to get the best value.

The Bottom Line: An IP Rating is a Promise

An IP rating is a clear, standardized promise from the manufacturer about where their product can survive and thrive. It takes the guesswork out of your purchase and provides the confidence that your scale is a long-term asset, not a disposable liability.

Investing in the right protection upfront is always cheaper than replacing a broken scale and dealing with the operational chaos it causes.

Operating in a tough environment? Our full range of IP66 Rated Scales and Stainless Steel Washdown Scales are engineered to withstand your daily challenges.

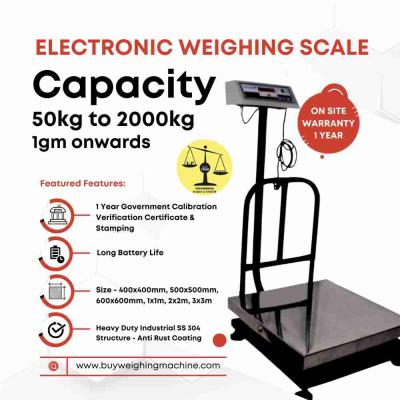

Weighing Scale

Weighing Scale