Trust, But Verify: Why Scale Calibration is Your First Line of Defense

It happens slowly, almost imperceptibly. A gram here, a pound there. Your industrial scale seems fine, but over weeks and months, a subtle drift occurs. Maybe it's temperature changes, maybe it's the wear and tear of a heavy item being dropped, or perhaps it's just the natural aging of components.

Then, you find out you've been shipping 100.5 kg instead of 100 kg for months. Or worse, you've been receiving 990 kg of raw material but paying for a full ton. The small, invisible error becomes a very visible financial loss.

This is the silent threat that scale calibration exists to defeat. Calibration isn't a suggestion; it's the fundamental act of verifying that your scale tells the truth.

What is Scale Calibration? (It's Not What You Think)

Many people think calibration is "fixing" a scale. It's not.

Calibration is the process of comparing the reading of your scale to a known, traceable standard weight.

Think of it like setting a watch. You check your watch against the official atomic clock and adjust the hands to match. You're not repairing the watch; you're verifying and correcting its timekeeping. Scale calibration is the same. We place certified calibration weights on the scale and check if the display matches. If it doesn't, we "adjust the hands" by reprogramming the scale's internal settings until it does.

The Two Reasons You Can't Afford to Skip Calibration

1. It's About Profit Protection

Every inaccurate measurement has a direct financial impact. This is often called "shrinkage" or "giveaway."

- In Shipping: You give away product you aren't paid for.

- In Receiving: You overpay for raw materials.

- In Production: Your recipe ratios are wrong, leading to wasted ingredients and inconsistent product quality.

Regular calibration closes these leaks and protects your bottom line.

2. It's About Legal Compliance

If you use your scale for buying or selling goods by weight (buying scrap, selling grain, shipping freight), your scale is a legal-for-trade device. Regulatory bodies like the Weights and Measures division in most countries mandate regular calibration and certification. Using an uncalibrated scale for trade is illegal and can result in heavy fines and a loss of business license.

How Often Should You Calibrate Your Scale? It Depends.

There's no one-size-fits-all answer. The frequency depends on three key factors:

- How Often You Use It: A scale running 24/7 in a shipping department needs more attention than one used once a week.

- The Criticality of the Measurement: A scale used for legal trade or formulating expensive pharmaceuticals needs more frequent calibration than one used for general inventory.

- Your Operating Environment: Is the scale exposed to temperature swings, humidity, dust, corrosive chemicals, or physical shock (like heavy items being dropped)? Harsh environments demand more frequent checks.

A General Rule of Thumb: For most industrial scales in regular use, an annual calibration is the bare minimum. For high-use or critical applications, quarterly or even monthly intervals are common. Your scale manufacturer's manual is the best starting point for a recommendation.

The Calibration Process: What Does a Technician Actually Do?

When a certified technician arrives, they don't just push a button. They follow a rigorous process:

- Visual Inspection: Checking for physical damage that could affect performance.

- Cornerload Test: Placing a test weight in different areas of the platform to ensure consistency across the entire weighing surface.

- Linearity Test: Testing the scale's accuracy at multiple points across its range (e.g., at 25%, 50%, 75%, and 100% of capacity).

- Calibration Adjustment: Using certified, traceable weights, the technician adjusts the scale's internal settings to ensure its output matches the known standard across its entire range.

- Documentation: Providing a calibration certificate that documents the "as found" and "as left" conditions, proving the scale's accuracy and traceability to national standards.

Can I Calibrate My Scale Myself?

For non-critical, internal-use-only scales, you can perform a basic check with a known weight. However, for legal-for-trade or any scale where accuracy directly impacts cost or quality, self-calibration is not recommended or legally acceptable.

Why? The weights used must be certified and traceable to a national metrology institute (like NIST in the USA). The process must be documented to a standard. Without this, you have no proof of accuracy in an audit or dispute.

The Bottom Line: An Ounce of Prevention

Think of calibration not as a cost, but as one of the highest-return investments you can make in your operation. It is the simple, proven practice that ensures your data is reliable, your transactions are fair, and your processes are under control. In the world of weighing, if you can't trust your scale, you can't trust your numbers.

Don't gamble with your accuracy. Schedule professional On-Site Calibration Services with our certified technicians to ensure your scales are compliant, accurate, and protecting your profits.

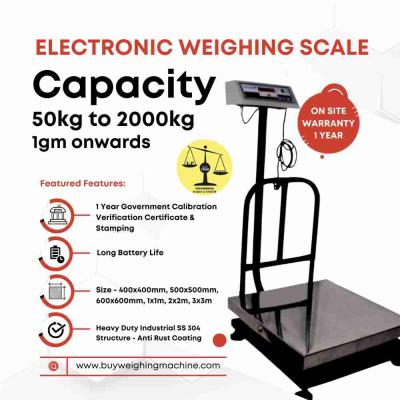

Weighing Scale

Weighing Scale