The Ultimate Guide to Industrial Weighing Scales: Choosing Your Business's Backbone

Let's be honest. In the world of industry, if you can't measure it, you can't manage it. And at the heart of measurement is the humble, yet utterly critical, industrial weighing scale. This isn't just about checking a weight; it's about profitability, safety, compliance, and efficiency.

I've been in this industry for over a decade, and I've seen everything from a small bakery almost going under because of an inaccurate bench scale, to a logistics company saving thousands after switching to the right floor scale. The right scale is an investment, not an expense.

So, let's demystify the world of industrial scales. By the end of this guide, you'll know exactly what you need.

What Exactly is an Industrial Weighing Scale?

At its core, an industrial weighing scale is a rugged, high-capacity device designed for demanding environments. Forget your bathroom scale—these workhorses are built to handle dust, moisture, heavy impacts, and constant use in places like factories, warehouses, shipping docks, and farms. They provide precise measurements for everything from tiny electronic components to multi-ton trucks.

The Major Types of Industrial Scales and Their Superpowers

Here’s a breakdown of the most common types you'll encounter. Think of this as your "scale family tree."

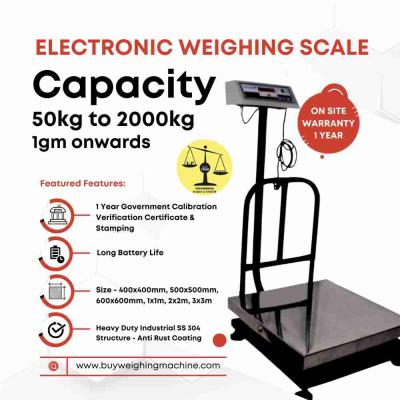

1.) Platform Weighing Scales

These are the all-rounders of the industrial world. They feature a low-profile platform onto which items are placed for weighing.

- Common Uses: Warehouses for pallet weighing, manufacturing for component counting, factories for batch weighing.

- What to look for: Size (make sure it fits your pallets!), capacity (don't max it out constantly), and durability. A common mistake is buying a scale with a platform that's too small, leading to unstable and inaccurate weighing.

2.) Floor Scales & Heavy-Duty Industrial Platform Scales

When platform scales need a big brother, you get floor scales. These are heavy-duty, flush-to-the-floor solutions designed for massive loads. The terms are often used interchangeably, but "heavy-duty" usually implies an even more robust construction.

- Common Uses: Weighing full trucks on a pitless scale, large metal coils in a steel mill, industrial machinery.

- What to look for: Construction quality (all-steel is best), waterproofing rating (IP67 is gold standard for washdown environments), and capacity. For truck scales, you need a minimum of 60,000 lbs capacity.

3.) Crane Scales

Why bring the item to the scale when you can bring the scale to the item? Crane scales hang from a hoist or crane hook, allowing you to weigh loads mid-lift. It’s a fantastic space-saver and safety tool.

- Common Uses: Foundries, scrap yards, shipping ports, any application involving overhead cranes.

- What to look for: Safety factor (it should be much higher than the rated capacity), remote display (so the operator can see the weight from the ground), and robust wireless connectivity.

4.) Bench Scales

Smaller than platform scales, these are designed to sit on a counter or bench. They are the workhorses for smaller parts, mail rooms, and quality control checks.

- Common Uses: Portion control in food processing, counting small parts in inventory, postal and shipping services.

- What to look for: Resolution and accuracy (especially important for parts counting), and the size of the weighing pan.

The "Electronic" Heart: How Do Electronic Weighing Machines Work?

Almost all modern scales are "electronic weighing machines." But what does that mean? It's all about strain gauges.

In simple terms, when weight is applied to the scale's platform, it causes tiny, precise deformations in a metal component called a load cell. The strain gauges attached to this load cell change their electrical resistance when stretched or compressed. This change is measured by the scale's indicator and converted into a digital weight reading.

This is why build quality matters. A cheap load cell can drift with temperature changes or get permanently damaged by overload, giving you inaccurate readings for life.

How to Choose the Right Scale: A 5-Point Checklist

Don't just buy the first scale you see online. Ask these questions:

- What is your MAXIMUM weight? Not the average, the maximum. Then, add a 10-20% safety margin. Overloading is the #1 killer of scales.

- What is the SMALLEST weight change you need to see? This is your resolution. Weighing trucks? 20 lbs increments are fine. Weighing gold? You'll need 0.001g precision.

- What is your environment like? Is it wet? Dusty? Corrosive? Explosive? This determines the IP rating and construction material (e.g., stainless steel for washdown).

- What size are your items? Your scale platform must be large enough to hold your items safely and stably.

- What features do you need? Do you need parts counting, percent weighing, data transfer to a printer/PC, or battery portability?

The Bottom Line

Choosing the right industrial scale is a technical decision with a direct impact on your bottom line. An accurate, reliable scale prevents product giveaways, ensures you're not overpaying for raw materials, and keeps your processes running smoothly.

When in doubt, talk to a specialist. A five-minute conversation can save you from a five-thousand-dollar mistake.

Ready to find your perfect scale? Explore our range of rugged and reliable Platform Scales and Heavy-Duty Floor Scales designed for your industry's toughest challenges.

Weighing Scale

Weighing Scale