More Than Just a Pallet Scale: Unlocking the Full Potential of Your Platform Weighing Scale

Walk into any warehouse, factory, or shipping dock, and you're almost guaranteed to see one: the reliable platform weighing scale. It's the unsung hero of the industrial world, quietly ensuring shipments are correct, inventory is accurate, and production batches are perfect.

But here's the thing most people miss: not all platform scales are created equal. I once helped a packaging company solve a chronic "shrinkage" issue. They were using a heavy-duty floor scale for all their pallets, but for their small, outgoing parcels, they were just... guessing. The moment we integrated a dedicated, high-accuracy platform scale into their packing line, their shipping costs became predictable, and customer disputes vanished.

A platform scale is more than just a place to put heavy things. It's a strategic business tool. Let's find the right one for you.

What is a Platform Weighing Scale, Really?

At its simplest, a platform scale is a freestanding scale with a flat, elevated platform (hence the name) and a digital indicator. They are the go-to solution for weighing items that are too large or heavy for a bench scale but don't require the massive, permanent installation of a floor scale.

Their superpower is versatility. From weighing boxes and drums to counting parts and weighing animals, the applications are nearly endless.

Not All Platforms Are the Same: Choosing Your Configuration

This is where the critical decision lies. Picking the right configuration from the start saves time, money, and frustration.

1.) The Low-Profile Platform Scale

This is the most common type you'll see. Designed with a low height for easy roll-on or placement of items, often using a ramp.

- Ideal For: General warehouse pallet weighing, manufacturing components, drum weighing, logistics.

- The Big Advantage: Ergonomics. You're not lifting items high off the ground. Forklifts can easily slide pallets on and off.

- Pro Tip: Always check the ramp's weight capacity. A cheap ramp can bend under a fully loaded pallet, creating a safety hazard.

2.) The Pit Mounted Platform Scale

For the ultimate in space-saving and workflow efficiency, you can't beat a pit scale. The scale is installed into a pit in the floor, making the weighing surface flush with the surrounding concrete.

- Ideal For: High-traffic areas where forklifts are constantly moving, production lines where items need to be rolled seamlessly from one area to another.

- The Big Advantage: Uninterrupted workflow. No ramps to navigate. It becomes an invisible part of your process.

- The Catch: Requires significant construction and upfront cost to dig the pit and install proper drainage.

3.) The Portable/Pallet Scale

Mobility is its middle name. These scales are often battery-powered and sometimes even feature forklift pockets, allowing you to move the scale to the item, not the other way around.

- Ideal For: Businesses with multiple loading bays, inventory checks in different parts of a warehouse, farms, or rental operations.

- The Big Advantage: Flexibility. One scale can serve multiple locations.

- Watch Out For: Battery life. Ensure it can last a full shift, and make sure the design is robust enough to handle being moved while still protecting the sensitive load cells.

Key Features That Separate the Good from the Great

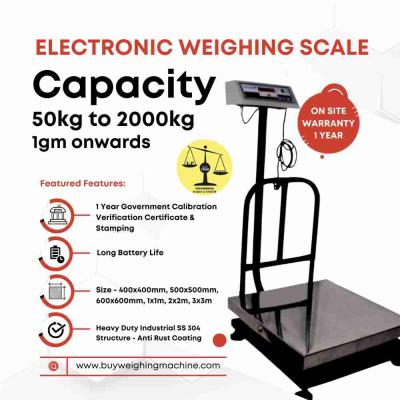

When you're comparing models, don't just look at the price tag. Look for these critical features:

- Construction Material: Is it painted carbon steel or full stainless steel? For any environment involving moisture, chemicals, or food, stainless steel is worth every penny for longevity.

- IP Rating: Remember our talk from yesterday? A scale with an IP66 or IP67 rating can survive being hosed down, a common need in food and chemical industries.

- Indicator Capabilities: Does it just show weight, or can it do more? Look for parts counting, checkweighing (under/over target), and accumulation features. The ability to connect to a printer or computer via RS-232, USB, or Ethernet is a huge plus for data management.

- Corner Load Compensation: A high-quality scale will give you the same accurate reading whether the item is placed dead-center or off to the side. Cheaper models can vary significantly.

Your 5-Step Platform Scale Selection Checklist

Before you click "buy," ask these questions:

- What is my maximum pallet or item weight? (Add a 20% safety margin).

- What platform size do I need? It must be larger than the footprint of your largest pallet or item for stable weighing.

- How mobile does it need to be? Will it live in one spot, or does it need to travel?

- What is my operating environment like? (Indoors/Outdoors? Dry/Hosed down?).

- What data do I need? (Just a weight on the screen, or printed tickets/data sent to my system?).

The Bottom Line

A platform weighing scale is an investment in efficiency and accuracy. Choosing the right one streamlines your workflow, reduces manual handling, and provides the data you need to make smarter business decisions. It’s not just about weighing things; it’s about moving your business forward with confidence.

Working with sensitive materials or in wet environments? Our range of Stainless Steel Platform Scales are built to withstand the toughest conditions while delivering pinpoint accuracy.

Weighing Scale

Weighing Scale