Crane Scale vs. Platform Scale: The Ultimate Decision Guide for Material Handling

The Overhead vs. The Ground Game: Choosing Your Champion for Heavy Lifting

In the arena of heavy industry, two titans of weighing often face off: the Crane Scale, operating from the heavens of your facility, and the Platform Scale, holding firm on the factory floor. I've seen the same internal debate play out in countless plants: "Should we install a big platform in the aisle, or just hang a scale from our crane?"

The wrong choice doesn't just mean a less efficient process. It can mean a perpetual bottleneck, a safety compromise, or a scale that never gets used. This isn't about which is better; it's about which is better for you.

Let's cut through the noise and match the tool to your task.

The Core Philosophy: Two Different Paths to the Same Goal

- Platform Scale Philosophy: Bring the load to the scale. You move your item (with a forklift, pallet jack, or manually) to a dedicated weighing station on the ground.

- Crane Scale Philosophy: Bring the scale to the load. You integrate weighing into your existing lifting process. The scale becomes part of the crane or hoist.

Head-to-Head: The Decisive Factors

| Decision Factor | Platform Scale | Crane Scale |

|---|---|---|

| Primary Workflow | Dedicated weighing station. A separate step in the process. | Integrated weighing. Weighing occurs during the essential lift/move. |

| Space Requirement | High. Requires clear floor space for the scale and maneuvering room. | Very Low. Utilizes existing overhead space. Zero floor footprint. |

| Speed & Efficiency | Slower. Requires double-handling: move to scale, weigh, move to destination. | Faster. Weighs in a single motion during the necessary transport lift. |

| Ideal Load Type | Pallets, drums, boxes, stable items that can be set down. | Awkward, large, or hot items (coils, castings, molds, machinery). Items that are difficult or unsafe to ground. |

| Typical Capacity Range | 500 kg to 10,000 kg (1,100 lbs to 22,000 lbs) and beyond for floor scales. | 1,000 kg to 50,000 kg (2,200 lbs to 110,000 lbs) and higher. Often used for the heaviest singular loads. |

| Data Integration | Excellent. Often stationary with easy power & data cable connections. | Good. Relies on robust wireless (RF) transmission to remote displays & printers. |

| Safety Focus | Stability of load on platform; preventing overload. | Critical. Safety Factor (e.g., 4:1), hook integrity, and dynamic load safety are paramount. |

Real-World Scenarios: Which One Wins the Job?

Scenario A: The Scrap Metal Yard

- Process: Weighing incoming truckloads of loose scrap and outgoing bales.

- Winner: Crane Scale. The material handler grapple can pick up a pile, weigh it in mid-air, and drop it directly into the shredder or onto a pile. A platform scale would be impossible for loose scrap and a bottleneck for bales.

Scenario B: The Warehouse Shipping Dock

- Process: Verifying the weight of standard, palletized goods for accurate freight billing.

- Winner: Platform Scale. A low-profile scale with ramps allows a forklift to quickly roll a pallet on, get a stable weight, and roll it off into the truck. It's fast, stable, and perfect for standardized loads.

Scenario C: The Steel Service Center

- Process: Weighing massive, 10-ton steel coils for inventory and sale.

- The Dilemma: Both could work.

- Platform Scale: Requires a massive, expensive floor scale and precise coil placement.

- Crane Scale: Weighs the coil as it's being moved by the overhead crane anyway—no extra step. Likely Winner: Crane Scale for sheer process integration.

The Hybrid Approach: When You Need Both

Many large facilities are not one-or-the-other. They use a combination:

- Crane Scales in the raw material/receiving area for massive, awkward items.

- Platform Scales in the packaging/shipping area for finished, palletized goods.

This layered approach optimizes each stage of the workflow.

Your 5-Question Decision Driver

Answer these to find your champion:

- Is the item already being lifted by an overhead crane or hoist as part of its normal movement? (If YES, lean strongly towards Crane Scale).

- Do I have clear, stable floor space for a permanent weighing station? (If NO, Crane Scale is your only option).

- Is the load stable and easy to place on a flat surface? (If NO, due to size, shape, or temperature, Crane Scale is safer).

- Is my goal maximum speed for a repetitive, pallet-based process? (If YES, a dedicated Platform Scale lane is often faster).

- What is my single heaviest item? (For extreme weights >20 tons, Crane Scales often offer a more economical high-capacity solution).

Critical Considerations for Each Choice

If Choosing a Crane Scale:

- SAFETY FACTOR IS KING. Never use one rated below 4:1. It is lifting equipment first.

- Factor in the cost of a high-visibility remote display for the crane operator.

- Consider power: solar is excellent for outdoor yards, batteries for general use.

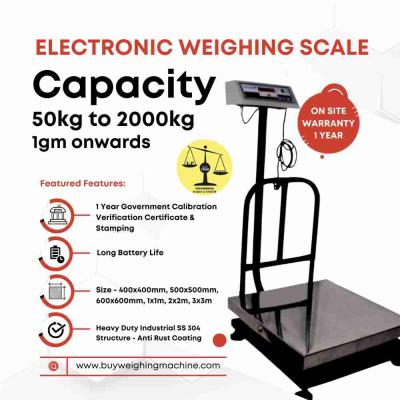

If Choosing a Platform Scale:

- Ensure the platform size is larger than your largest pallet or item footprint.

- Choose the right construction: stainless steel for washdown, carbon steel for dry warehouses.

- Ramps are critical. Ensure they are rated for the same load as the scale.

The Bottom Line: It's About Your Process Flow

A Platform Scale is a dedicated destination for weighing.

A Crane Scale is a tool that makes weighing a byproduct of movement.

Map your material's journey through your facility. The point where weighing needs to happen will loudly announce which scale type belongs there. Choose the one that removes a step, not adds one.

Still mapping your workflow? Contact our material handling specialists for a free, on-site or virtual consultation. Explore our robust Industrial Crane Scales and efficient Low-Profile Platform Scales to see your options.

Weighing Scale

Weighing Scale