Bench Scale vs. Platform Scale: The Definitive Guide to Choosing Your Weighing Workhorse

It’s a classic scene in my line of work. A business owner points to a corner of their workshop and says, “I need a scale for over there. Something good.” But when I ask what they’ll be weighing, the answer is often a long list: “Well, small parts for kits, sometimes a full carton of them, and oh—we get these 50-pound drums of material every month…”

This is where the critical choice between a bench scale and a platform scale comes into sharp focus. Picking the wrong one means either constantly maxing out a small scale (and breaking it) or wasting money and space on a scale that’s overkill for 90% of your tasks.

Let’s end the confusion. Here’s your no-nonsense guide to making the right call.

The Core Difference: It’s All About the Stage

Think of it like this:

- A Bench Scale is your precision workstation. It’s designed for tasks that require attention to detail, often while sitting or standing at a counter. It’s for smaller, lighter items where accuracy is paramount.

- A Platform Scale is your loading dock. It’s built for heavier, bulkier items that are moved with equipment like pallet jacks or forklifts. It’s about capacity and durability.

Head-to-Head Comparison: Breaking Down the Specs

| Feature | Bench Scale | Platform Scale |

|---|---|---|

| Primary Use Case | Counting small parts , quality control checkweighing, packaging, portioning. | Weighing pallets, drums, large cartons, raw material batches. |

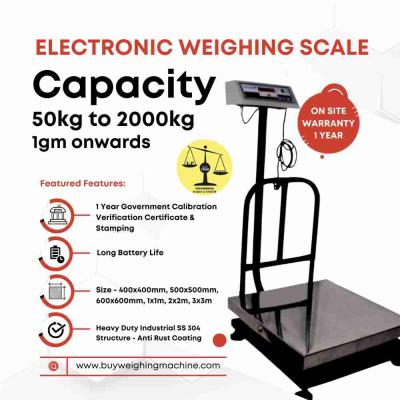

| Typical Capacity | Low to medium (e.g., 5 kg to 150 kg / 10 lbs to 300 lbs). | Medium to high (e.g., 150 kg to 2,000 kg / 300 lbs to 5,000 lbs). |

| Platform Height | Higher (designed to sit on a bench or stand). | Low-profile (designed for roll-on access, often with ramps). |

| Portability | Highly portable. Easy to move from station to station. | Semi-portable to stationary. Can be moved with equipment, but not designed for daily relocation. |

| Key Features | High resolution, parts counting, checkweighing, touchscreen interfaces. | Rugged steel construction, low profile, large numeric displays, often battery-powered for dock use. |

| Ideal Environment | Labs, packaging stations, assembly lines, offices, retail backrooms. | Warehouses, shipping/receiving docks, factories, farms. |

| Price Point | Generally lower initial investment. | Higher initial investment due to robust construction and higher capacity components. |

Real-World Scenarios: Which Scale Saves the Day?

Scenario 1: The Electronics Assembler

- Task: Counting thousands of tiny resistors and capacitors for circuit board kits.

- The Right Choice: Bench Scale. A high-precision bench scale with a parts counting function will be fast, accurate, and can sit right on the assembly table. A platform scale would be impossible to use for this task and wildly inaccurate.

Scenario 2: The Small-Batch Manufacturer

- Task: Weighing 25-pound bags of powdered ingredients for mixing, and also weighing the final 50-pound boxes for shipping.

- The Right Choice: Both, but start with a Platform Scale. A mid-capacity platform scale (e.g., 300 lbs) can handle both tasks well. The bags and boxes can be easily placed on its low platform. A bench scale would be constantly overloaded by the boxes.

Scenario 3: The Warehouse Manager

- Task: Verifying the weight of outbound pallets to ensure correct freight charges.

- The Right Choice: Platform Scale. A heavy-duty, low-profile platform scale with ramps allows a pallet jack to roll the loaded pallet on and off easily. A bench scale is not an option here.

The Hybrid Solution & When to Upgrade

Many businesses start with a bench scale for small tasks and then realize they need a platform scale for bulk items. That’s a normal growth path.

The Upgrade Trigger Signs:

- You are consistently weighing items that are awkward or heavy to lift onto a bench.

- Your items weigh more than 75% of your bench scale’s capacity.

- You are using a pallet jack or forklift to move items that need to be weighed.

Can one scale do it all? For a very wide range of items, you might consider a portable platform scale with a high resolution. It can be placed on a bench for light items or on the floor for heavier ones, but it may not excel at ultra-fine counting tasks.

Your 5-Question Decision Checklist

Answer these, and the right choice will become clear:

- What is the single heaviest item you will weigh? (If over 150 kg/300 lbs, think platform).

- What is the smallest, most precise measurement you need? (If it’s grams for counting, think bench).

- How will the item get to the scale? (Carried by hand = bench. Rolled on wheels = platform).

- Where will the scale live? (On a dedicated counter = bench. On the warehouse floor = platform).

- What is your workflow? (Is it a stationary inspection point, or does it need to serve multiple areas?).

The Bottom Line: Match the Tool to the Task

A bench scale is a precision instrument for focused tasks. A platform scale is an industrial appliance for material handling. Buying the right one the first time means a smoother workflow, protected accuracy, and a scale that lasts for years instead of burning out in months.

Don’t force a tool to do a job it wasn’t built for. The right scale pays for itself in efficiency and reliability.

Still unsure which type fits your unique needs? Contact our experts for a free consultation. Or, explore our curated selections of Industrial Bench Scales and Low-Profile Platform Scales.

Weighing Scale

Weighing Scale